Some Known Details About American Plastics

Table of Contents10 Easy Facts About American Plastics ExplainedUnknown Facts About American PlasticsAbout American PlasticsNot known Factual Statements About American Plastics American Plastics Things To Know Before You Get This

A little homework can aid you with time. It is hard to evaluate its top quality at initial glimpse with the appearance of HDPE pipe installation, many flaws are revealed when making use of, so we can only have a correct judgment after usage. It is needed to select HDPE pipe installations made by a professional manufacturer with an excellent online reputation and reputation.

A technological expert is essential for a great product, especially in the production sector, due to the fact that a small error will certainly bring about the failing of the whole task. HDPE pipelines can replace concrete pipes in field systems to save time and cost of fixing broken or burst pipelines. HDPE pipe is also a much less expensive alternative contrasted to various other piping materials in regards to operating and installment prices.

The Basic Principles Of American Plastics

HDPE pipelines are made with solid straight or bent areas. The pipes are not fragile and can be easily put right into a bent area without extra jointing or welding.

Chemicals resistant to HDPE pipes can infect the pipe. The pipeline does not function with chemicals and does not shed heat or electricity.

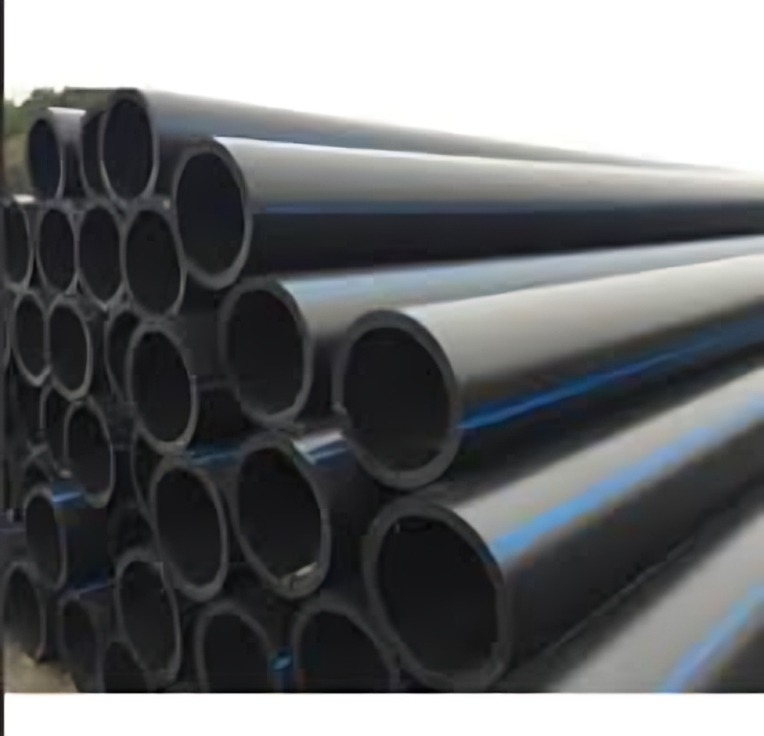

HDPE pipelines are normally strong and immune to damage triggered by exterior loads, high pressure or vibration - https://www.provenexpert.com/american-plastics/. The pipelines can stand up to handling and bend also in winter. Safe eyeliner HDPE internal tubes Smooth Line Pipe Gliding lining making use of roller combinations Pipe explosion Plastic pipes systems Construction of brand-new pipelines Corrosion resistance, no leaking, high longevity

Heat integration, while its challenges exist, can create solid and trustworthy joints. Answers: The toughness and longevity of HDPE can be gauged by its ability to hold up against temperatures of around 248F in the brief term and even a consistent 230F. If your application includes gas and liquid to accessibility and raise those temperatures, HPDE piping is a trustworthy service.

The 20-Second Trick For American Plastics

A potable water line/potable water pipe is always dark with blue stripes and pipes passing through liquids, fluids under pressure, and process gases are always loaded with a yellow or black coat with yellow lines. HDPE pipeline material have actually been used in the general market for over 50 years and their outcomes are astonishing, developing self-confidence among producers that they are much more concentrated on HDPE pipeline remedies.

Times since 1991 Removal of material demands with gauge and adjustment. In the stress fracture resistance examination the cellular division needs were deteriorated. It is practical to conclude that HDPE pipeline built today might have.

Each size category is developed remembering the demands of pressure, flow rate, and environmental variables of the intended application. By matching the proper HDPE pipe dimension to its usage, engineers and specialists can optimize efficiency and prolong the lifespan of their piping systems. Dimension and size are related concepts in the context of HDPE pipes.

Get This Report about American Plastics

As specified earlier, pipelines with reduced SDR values are able to endure higher pressures, which is a crucial factor to consider in the selection process for tasks that entail high pressure or important applications. Texas hdpe pipe manufacturer. Selecting a pipe with an unacceptable SDR could result in system failure, security risks, and expensive repair work. Selecting the appropriate HDPE pipeline dimension is essential for the success and performance of any kind of piping system

Application Specifics: Customize your pipeline dimension choice to the specific needs of its application, whether for municipal, commercial, or other uses. Recognizing how the HDPE pipe will be utilized, the anticipated flow rates and the pressure requirements are vital. As an example, high-pressure applications might call for a pipeline with a better wall density to withstand the internal tensions, while a lower-pressure, high-flow system might prioritize diameter dimension to minimize friction loss.

The American Plastics Ideas

Follow these actions: Assess the Application: Identify the pipe's planned usage, consisting of ecological elements and solution conditions. Determine Circulation Rates: Use industry-standard calculations or software to estimate the peak and standard circulation prices. Understand Pressure Needs: Determine the stress score needed based upon system demands. Describe SDR: Examine the conventional dimension proportion to discover a pipeline that can manage the required stress.

Selecting the best HDPE pipeline dimension is a fragile equilibrium in between countless technical specs and useful demands - https://www.merchantcircle.com/american-plastics-midland-tx#tips. With mindful consideration and accurate calculations, you can make certain the size of look these up the pipe you pick will certainly serve your demands properly and successfully. Selecting the correct HDPE pipe dimension is essential for system efficiency, longevity, and cost-effectiveness

Recognizing these facets will make certain optimum performance and compatibility throughout your piping system - HDPE Pipe for Oilfield. The awaited flow price or volume of the liquid being carried is just one of the primary components in pipe size option. A pipeline that is as well tiny can limit circulation, triggering pressure loss and prospective obstructions, while an extremely large pipeline might cause unnecessary cost and decreased system effectiveness